Priscilla, our 1940 17-foot Barrelback “lab rat” experiment is progressing rapidly now that we finally took delivery and milled the Meranti mahogany planking needed to complete her True 5200 bottom. As we shared in our last update, rather than install her inner skin using 6 mm plywood panels, we are reverting to what is a truly very old school alternative: replacing the inner skin using strips of planking laid at approximately 45 degrees to the keel.

In so doing, we will deliver a bottom, the inner skin of which precisely matches that installed in Algonac in 1940.

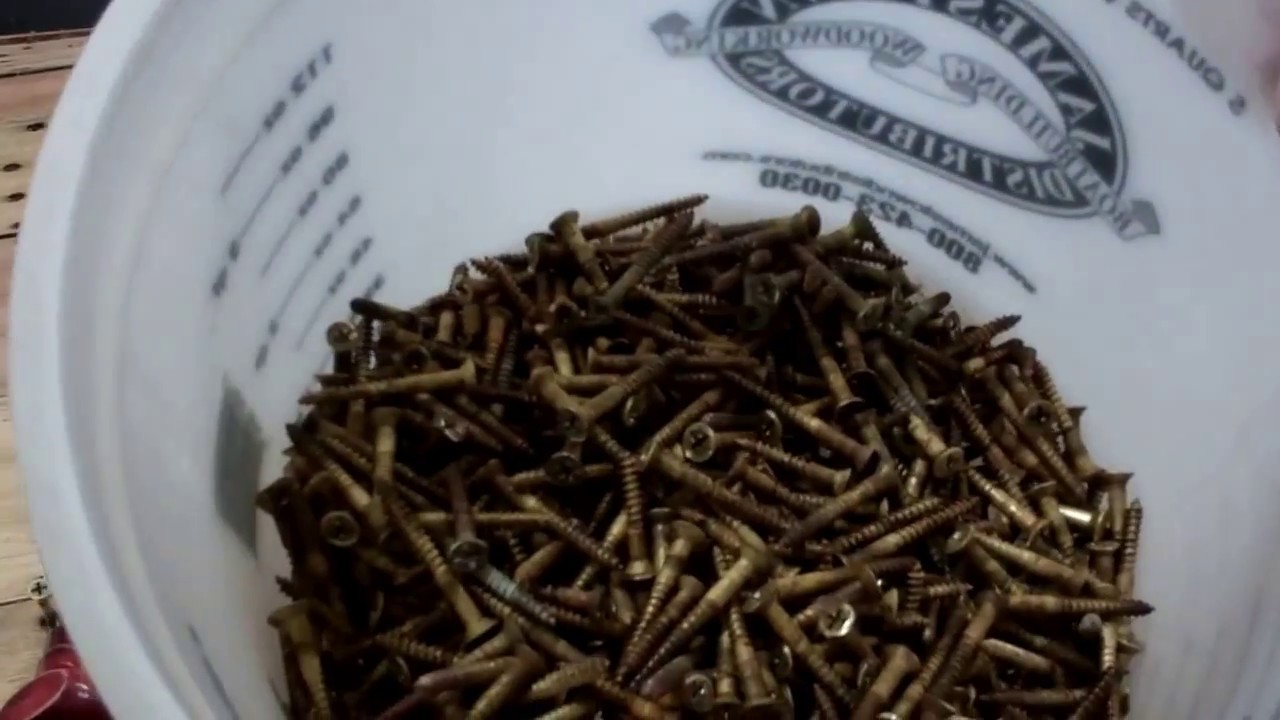

Once we dry-fitted each, approximately 5-3/4”-wide plank, everything was sealed with four coats of Smith’s CPES, after which we have applied three coats of Chris-Craft mahogany bilge paint to their inner surfaces. Next, we installed these planks bedded in mahogany 5200 using #6×1” Frearson-drive, flathead silicon bronze wood screws.

Happily, her bilge now presents exactly as it did when Priscilla left Algonac in 1940.

Planking the inner skin produces a tighter, more rigid skin that follows the bottom’s contours precisely. Any interior squeeze-out will be removed using nylon putty knives before it, too, receives three full coats of Chris-Craft mahogany bilge paint.

Post this experiment, SMB will make individually planking inner skins our standard for SMB True 5200 bottoms.

With the Meranti planking in-hand, and having milled it to land fair with the chines, and began dry fitting it to her bottom. Our first step involves measuring both bottom faces at their widest point between the keel and the chine.

Here, and as we’ve shared with you earlier, we once again confirmed that Chris-Craft’s rule-of-thumb was operating at Algonac when her hull was being laid out. She is 7/8” wider on port than she is on starboard at the widest point between her keel and chines. And, at the transom, she is a 1/2” wider on starboard than she is on port.

Joe will dry fit and fasten the outer planks temporarily, working from her keel to her chines. Once laid out completely, the planks will be released and sealed on all sides with four coats of Smith’s CPES. We will also apply one final “insurance” coat of CPES to her inner skin’s bottom.

The final assembly step involves bedding each outer plank in an at least one-eight-inch-thick bed of white 3M5200, before fastening them with #8×1-1/4” flathead silicon bronze wood screws. Finally, and that’s when she really begins looking good, we apply five coats of Interlux InterProtect 2000E Barrier Coat Epoxy Primer, with alternating gray and white coats, which helps expose any holidays. Per Interlux’s instructions, 2000E should be applied in thin coats.