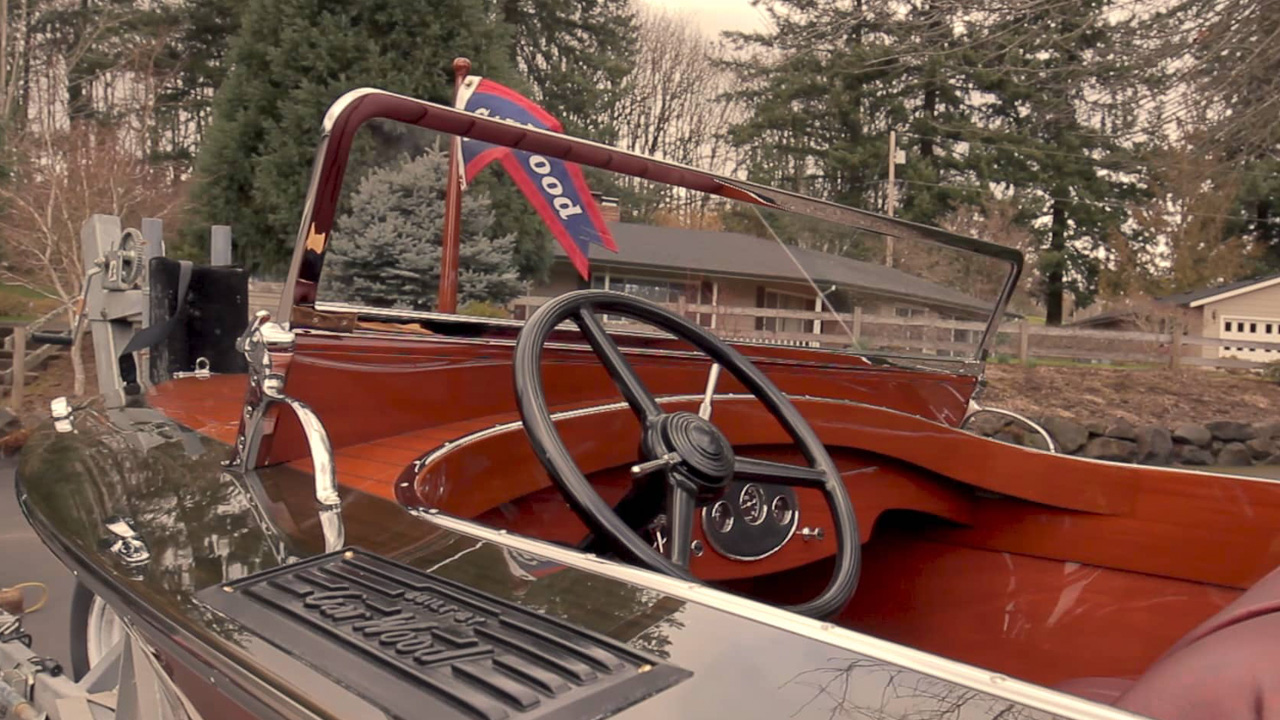

Our 1948 Truscott Barrelback Runabout has almost blasted through her True 5200 Bottom milestone! Her cousin, our 1948 Truscott utility’s stripping milestone is behind her.

I am now comfortable with having consigned both Truscotts to be fully preserved and resting on their identical Loadmaster custom trailers sitting on the green at the 2022 ACBS International Show in Burlington, VT, September 9 and 10. We hope to see you there!

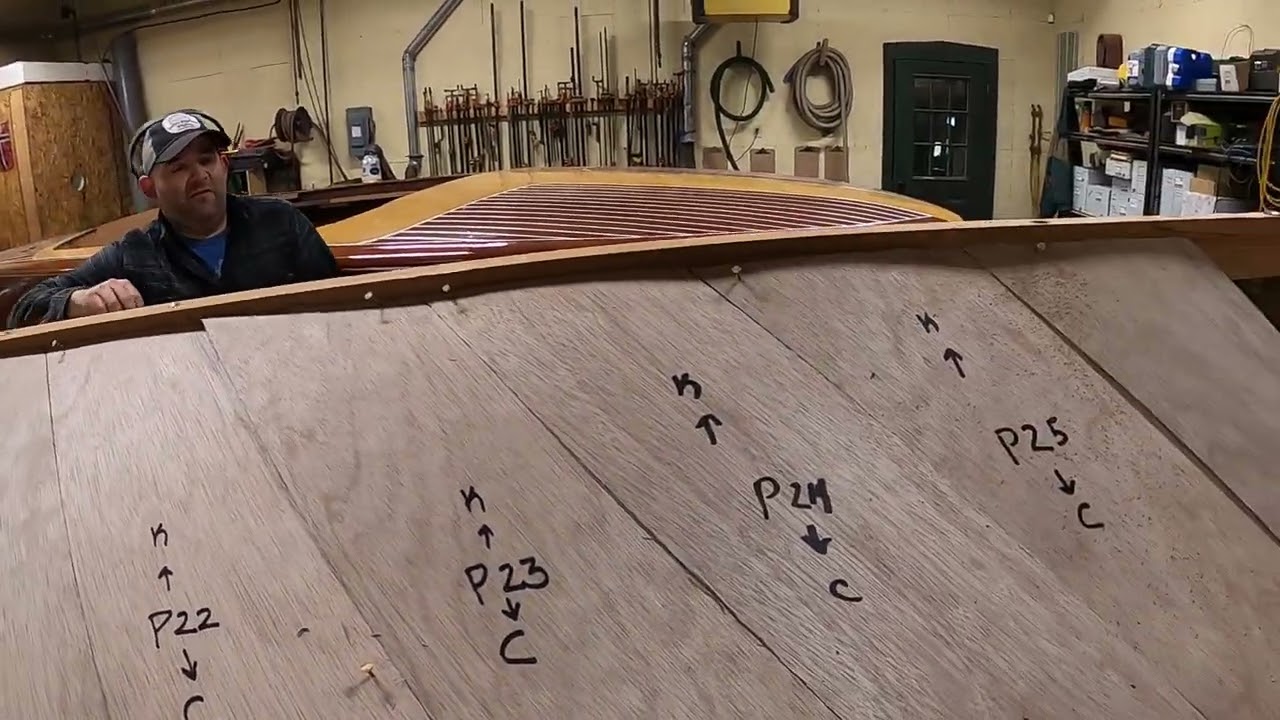

After replacing a couple of the runabout’s rotted bottom frames and installing a new inner skin comprised of 4 mm Meranti mahogany marine plywood six-inch-wide planks laid at an approximately 45 degree angle with respect to the chines and keel, all of which was bedded in 3M5200, we fabricated and installed outer planking using three-eighths FAS-grade Meranti mahogany plywood, also bedded in 3M5200.

It was all provisionally sanded fair. Rick is now almost finished filling countersinks and declivities 3M Premium Marine Filler. He will then sand the bottom, chines, hullsides and transoms fair a final time. However, we will then use her as a Don-Danenberg-inspired lab rat.

Don has just published yet another incredible how-to article, Using Common Sense Is Allowed, pp. 44-55, Classic Boating, July/August 2022, which is a must-read for anyone serious about wooden boat preservation. (To the fellow who savaged me, claiming “Don Danenberg is my friend, and I know he would never wet a hull down and cover it with plastic sheeting,” please pay attention …) “…The outside bottom of the hull can now be … be hosed down with fresh water.

“The next procedure I call pre-soaking. After the bottom planks are thoroughly wetted out, I cover the entire bottom with a very thin plastic sheet (.35 mil) and rub out all of the air bubbles as if the plastic were Saran Wrap. The thinner the plastic, the better this works. Cheap painters’ drop cloths work well. For the next two days peel up edges of the plastic to wet it and again rub out the air bubbles. This procedure changes the moisture content of the wood and causes it to swell, forcing out all excess rubber and, hopefully any trapped air.

“The equilibrium moisture content for the wood in your boat is dictated by the average relative humidity and temperature of the environment your boat lives in. For example, in most of the United States with lakes, it is in the 18% range, while in Arizona, it is 11%.

“Kiln dried mahogany from my suppliers is in the 6-10% range. Changes in overall moisture content of the wood can be retarded by protective coatings, not prevented. I know if this boat is to be kept in Michigan, this wood will eventually learn to exist at roughly 18% moisture content. Personally, I feel it wise to set it to this level before sealing it. (Claudon note: I received precisely the same advice from Don about the rest of the hull’s exterior planking.)

…

“When properly sealed against seasonal variations in relative humidity, this type of construction exhibits little or no expansion or contra traction great enough to crack the enamel paint at the plank seams. In order for this to work, of course, the bottom must be well sealed from excessive moisture absorption from extensive periods in the water.

“After two days of wetting the bottom, allow it to set for two more days until the moisture is noticeably absorbed and the surface appear dry. Remove the plastic and allow the surface to become completely dry. Now you must quickly cut off all the excess rubber, fill in all the screw holes, grind and fair the bottom, and get it sealed before it dries too much.” (pp 51, 55)

Unfortunately, we received Classic Boating and read Don’s piece after we began fairing the countersinks in our runabout’s bottom.

We will execute Don’s Pre-wetting procedure completely on the utility.

Priming – five coats of Interlux 2000E Barrier Coat Primer Will be followed followed by applying multiple coats of red hard antifoul paint.