Many of our boats still sport their (sometime original) traditional, usually double-planked bottoms. An inner skin is laid in on the diagonal, while the outer planks run lengthwise. An oiled canvas material, or plastic in the case of Penn Yan Striptite hulls, may be laid between the two skins.

Such hulls require soaking in to swell the bottom planking sufficiently that water infiltration shrinks to a minor nuisance.

All such bottoms must be stripped to bare wood and refastened where needed using silicon bronze, not stainless steel, screws.

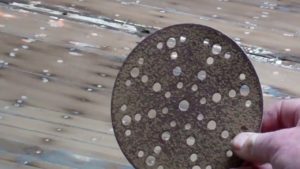

Sealing that raw wood with multiple coats – at least three – of Smith’s Clear penetrating Epoxy Sealer (CPES) is an absolute must. Doing so reduces the wood’s ability to absorb water dramatically.

We have seen and anguished over way too many bottoms where 3M5200 was forced into the plank seams in a misguided attempt at caulking them.

Owners and “restorers” go on a fool’s errand each time they pay fillets of 3M5200 into Lapstrake hulls’ inter-strake seams only to have the water that races by wash them away and those seams leak as much, if not more than they did originally.

Cured 3M5200 is dense and inflexible. It cannot compress as the neighboring planks swell, so the wood is compressed and even damaged beyond repair in the process.

This section introduces you to alternatives that provide a caulking action while not threatening the bottom planking.

1942 Century Imperial Sportsman: Why Filling Seams with 3M5200 Is Forbidden

1954 Penn Yan Captivator Aristocrat Transom Bottom Preservation

How to Caulk Seams With Cotton Roving – Palmer Launch Roxanne

1954 Penn Yan Captivator: How to Seal Bottom Seams using Thixo Flex

1954 Penn Yan Captivator Aristocrat Flipped