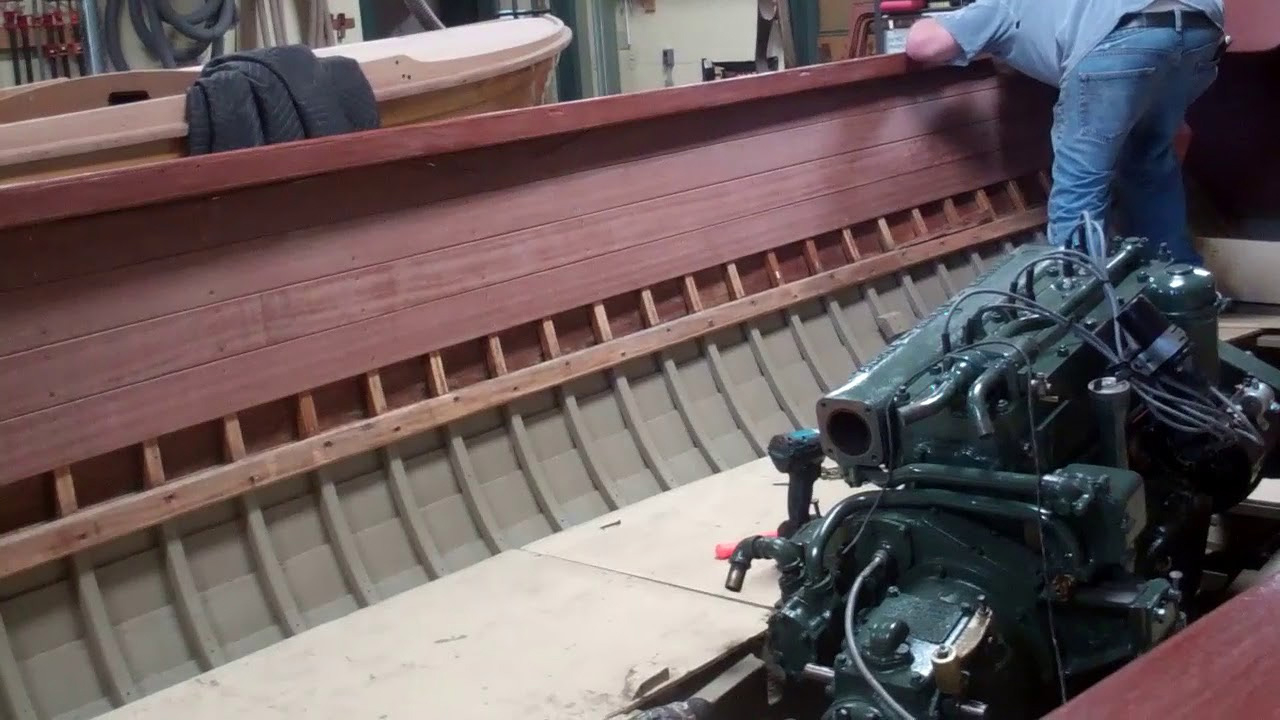

Her HIN is WR5167, and she is an example of Penn Yan “Stern Engined” inboard boats, powered by a twin carb Gray Marine Phantom 112-6.

According to Bob Speltz (Bob Speltz, The Real Runabouts VI, p. 213-14). Penn Yan offered four models. The Transport and President were utilities. The President and Aristocrat were runabouts. Three lengths, 16-ft, 18-ft and 19-ft were available, as were several engine options.

According to Speltz, “The ‘heavy stern/light bow’ balance produces uncommon action characteristics that delight all Penn Yan owners…

“A Penn Yan inboard could make the tightest turns, either way with a perfect ‘gravity’ bank. There was no skidding whatsoever. Running downwind in a heavy sea will find a Penn Yan being able to run wide open because it is light in the bow and heavy in the stern….

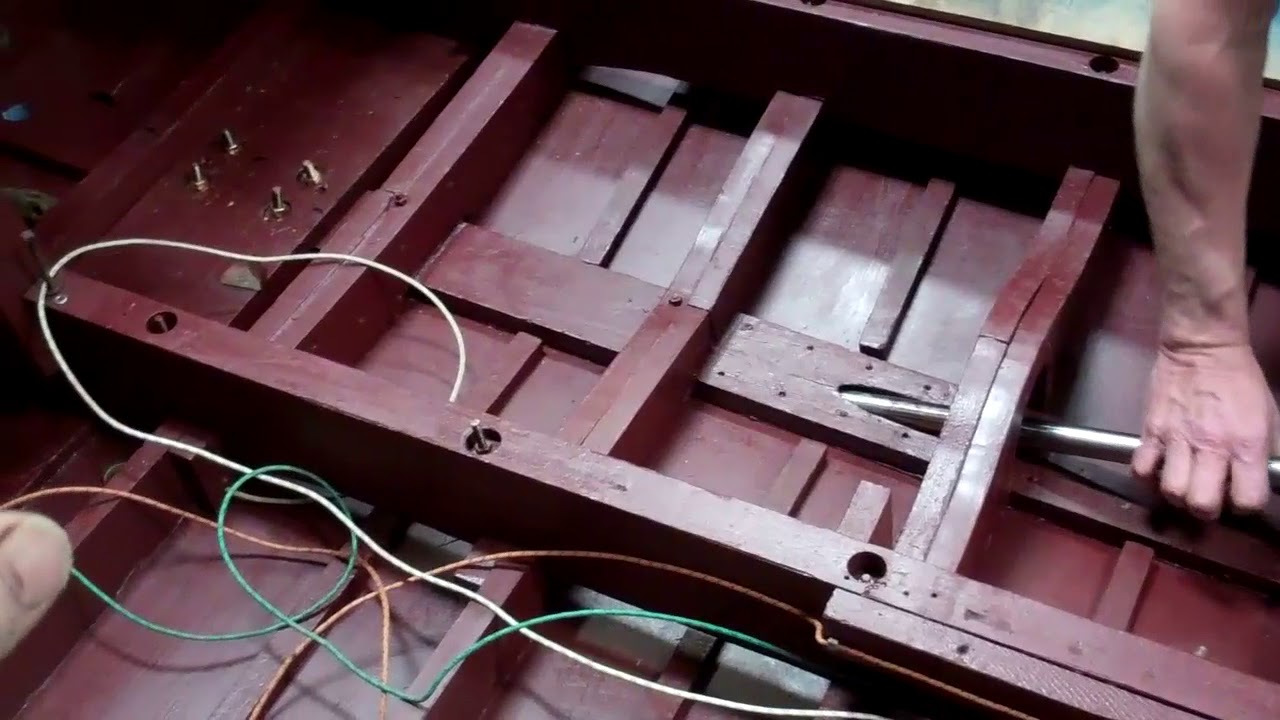

“The stern engine arrangement used by Penn Yan was used ever since 1932 and enjoyed great acceptance by all who owned such boats. Each Penn Yan inboard came equipped with a safety strut which was one piece bronze casting attached to the transom carrying both the prop shaft and rudder stock. It was so rugged it could hardly be destroyed…

“It has the effect of boat length behind the motor without hull buoyancy in that position, and that produced running characteristics we have already mentioned that were hard to believe.”

She must wait until winter 2019, but my goal is to preserve her then and have her on the water the following spring and summer.