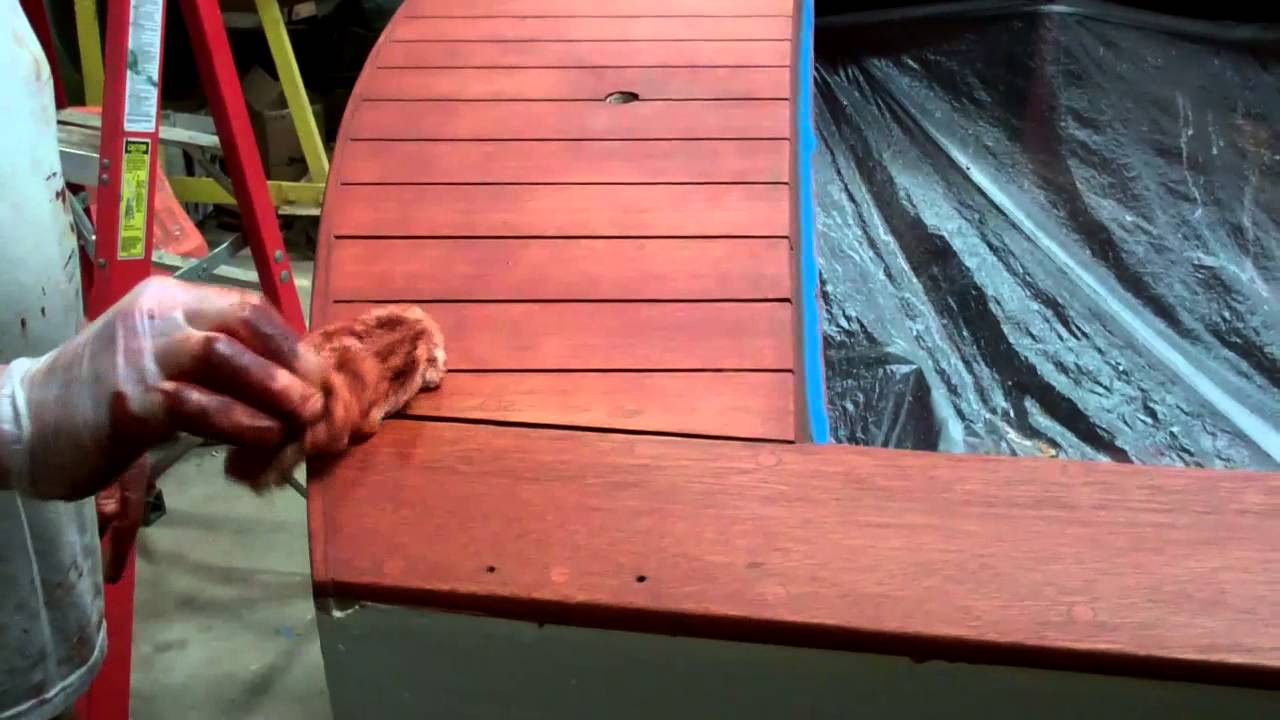

Staining day for the 1946 Gar Wood Ensign is complete.

Our aggressive bleaching, which involved keeping the wood well-soaked with bleach for 19 hours, created the perfect palette for the Interlux Interstain we scrubbed into the wood today.

That the process has worked as planned is clear from the homogeneity of the color across all surfaces, from the decks to the covering and then to the combing boards.

Notice the absence of any telltale dark rings around any of the bungs, and that the bungs, all of which are new, match the hues of the wood surrounding them perfectly.

Sealing is next, and here I will correct a misstatement I made in the previous Gar Wood staining day clip. While not always, and likely due to a chemical incompatibility between them, our occasional experience is that applying Smith’s CPES over Interlux Interstain seems to lift the stain here and there, but the result is absolutely unacceptable.

For that reason we use only two-part Interlux Clear Wood Sealer Interlux, a fast drying urethane used for priming wood prior to application of single part varnishes or two component urethane finishes, over Interlux Interstain.

The first coat of Pettit High-Build Varnish will be rolled and tipped on Friday!

1946 Gar Wood Ensign Staining Day

It is staining day for the 1946 Gar Wood Ensign.

Once we confirmed using our moisture meter that the wood is back to about 15% or less moisture content, we lightly hand sanded the entire surface with 80 grit dry paper, vacuumed it and then washed it down with Interlux 202 thinner.

As Ensigns were originally much browner than we are used to in the case of Chris-Craft boats, we mixed a 1:1 ration of two Interlux Interstain filler stain, Chris-Craft Mahogany (573) and brown mahogany (42). (Our customary Chris ratio is 2 red to 1 brown.)

We masked both covering boards at their intersection with the foredeck so we’d have more control over the process.

As with other projects, a full coat of stain is applied using a chip brush after which it is allowed to flash – become almost dull in appearance. Then cheesed cloth is used to scrub, and I mean really, really scrub, across the grain until we can discern a sheen across the surface.

We will complete the staining process by day’s end. The first of three coats of CPES will be applied tomorrow morning.

Varnish is not far away!

1946 Gar Wood Ensign Newly Planked & Ready for Bleach

We could not be more pleased to have reached this milestone. We knew we had no choice but to plank the decks anew, but she was holding another secret beneath her tired, split and just plain worn out original decking.

Not only were both decks dripped and broken away from their respective connections to the gunwales, the balance of the framing had become distorted and disconnected over time. When we positioned several trial planks across the foredeck, a pronounced and ill-positioned hump was evident on port, while the starboard side was essentially flat. The aft deck had similar issues.

Our strategy for addressing bringing the decks back to their proper shapes and strength involved releasing and re-fastening the individual elements under pressure. Once everything seemed to be in place, we fastened the newly-fabricated planks, holding our breath all the while.

That we succeeded is evident in this clip. The foredeck has regained its correct “domed” shape. The bulkhead is firmly attached at both ends. And RJ can stand on the deck without deflecting it.

Addressing the aft deck required releasing and replacing much of the framing as the end of most of the members had suffered serious degradation over the years.

Bleaching is next, followed by staining. Only then can we begin rolling and tipping coats of varnish.

1946 Gar Wood Ensign New Deck Milestone Reached Almost

Friday the 13th turns out to be a near milestone day for the 1946 Gar Wood Ensign deck planking project.

As it opens, you can enjoy with John and me seeing all the planking, fasteners and bungs in place, and all of the deck seams having been routed out.

What remains? As we explained in earlier reports, both decks were flying loose and sagging where they met the gunwales. That droop hid the fact that the deck boards we removed were actually thicker than are the covering boards. As a result, the new planking is proud of the covering boards now that the framework has been completed.

We use the Veritas Detail Flush-Cutting Saw, with a 26 TPI blade (05K34.10) for trimming the bungs fair with the surface. It is the first flush-cutting saw we’ve used that absolutely will not scratch the surface around the bung.

John’s final challenge, one that begins with 40 grit paper on our longboard sander, and ends with 80 grit, is to sand the decks fair with the covering boards.

Bleaching will follow as will follow, which we will chronicle for the community.

1946 Gar Wood Ensign Deck Planking Update

We are nearing a major milestone on the 1946 Gar Wood Ensign deck replanking portion of this preservation project.

Fabricating two small sections of planking, fastening them bedded in 3M5200, bunging the countersinks and sawing the excess away, and we will be ready for sanding and fairing the decks and covering boards.

Bleaching and staining will be next, followed by rolling, tipping and sanding coats of varnish.

We will be using Epifanes Gloss Clear Varnish on the decks and transom at the request of the owner.

1946 Gar Wood Ensign Project Re Launch One Year Later

A community member dinged us for apparently abandoning keeping all of you updated on the ’46 Gar Wood Ensign since we last presented her in February 2014. Well, the fact is that there was nothing to update. Yes, we replaced many topside fasteners and filled a myriad of bung holes before we faired, primed and applied the first coat of Interlux Premium Yacht Enamel – semi-gloss whit, #202. At that, and having exhausted his preservation fund, her owner asked us to put her in storage until now.

We’ve applied three more coats of the Interlux Premium to the topsides and finished laying out the boot stripe.

Now comes the deck planking and covering boards. RJ and I worked and worked to release the planking without harming it so we could clean, seal and then install it again with new silicon fasteners. (We also had to release the planking to get at the broken framing at the four corners of the cockpit.)

Try as we may, even the slightest pressure revealed through-and-through cracks and splitting in all but four planks. Gluing them together, save for the covering boards, which will remain on the boat, proved impossible, as applying the slightest amount of clamp pressure produced new cracks. The mahogany has simply lost its integrity, so, with heavy hearts, we are replanking all but the covering boards, the center plank on the aft deck, and possibly the king plank.

1946 Gar Wood Ensign Please Do NOT Fiberglass Wood Boats!

Here is the next installment on our 1946 GarWood Ensign restoration project. With everything removed from the hull, we have flipped her onto boat dollies in preparation for removing the planking, repairing all the failed, rotted and broken framework beneath them and then installing a 5200 bottom.

This boat spent most of her life on Squam Lake or Little Squam Lake in New Hamspire.

That these lakes have a well-earned reputation for unforgiving, rocky bottoms is evidenced by all the damage that this hull has suffered below the waterline. Indeed, the previous owner(s) installed iron strapping along the stem and forward sections of the keel. Then there is the through-and-through fracture of the keel just forward of the prop shaft tunnel.

Removing the fasteners and these straps was simple.

But then comes the fiberglass. Yes, someone fiberglassed the entire bottom, the chines and up the topsides as much as 8 inches. We “get” to remove all of it. Not doing so makes removing bungs and bottom plank fasteners all but impossible, never mind the fact that we are doing our utmost to preserve the original planks.

We have tried using chisels, which worked well along the keel and garboards, where sheets of fiberglass peeled off with relative ease.

However, the fabric-infused resin remained, and presents us with a challenge of much greater magnitude. It will be incredibly tedious and time-consuming, but using a combination of heat guns and sharpened putty knives seems to be the best solution. The challenge here is not gouging 60 year-old wood with the hot, sharp putty knife. We are also running into large areas of rot where water managed to breach the fiberglass skin and soaked the wood in a largely anaerobic environment.

We will soldier onward, but want to make a plea to all woody owners and preservationists, “Please, please do not fiberglass your wood boats!” Doing so is a lose-lose proposition, especially for these irreplaceable artifacts of the past.

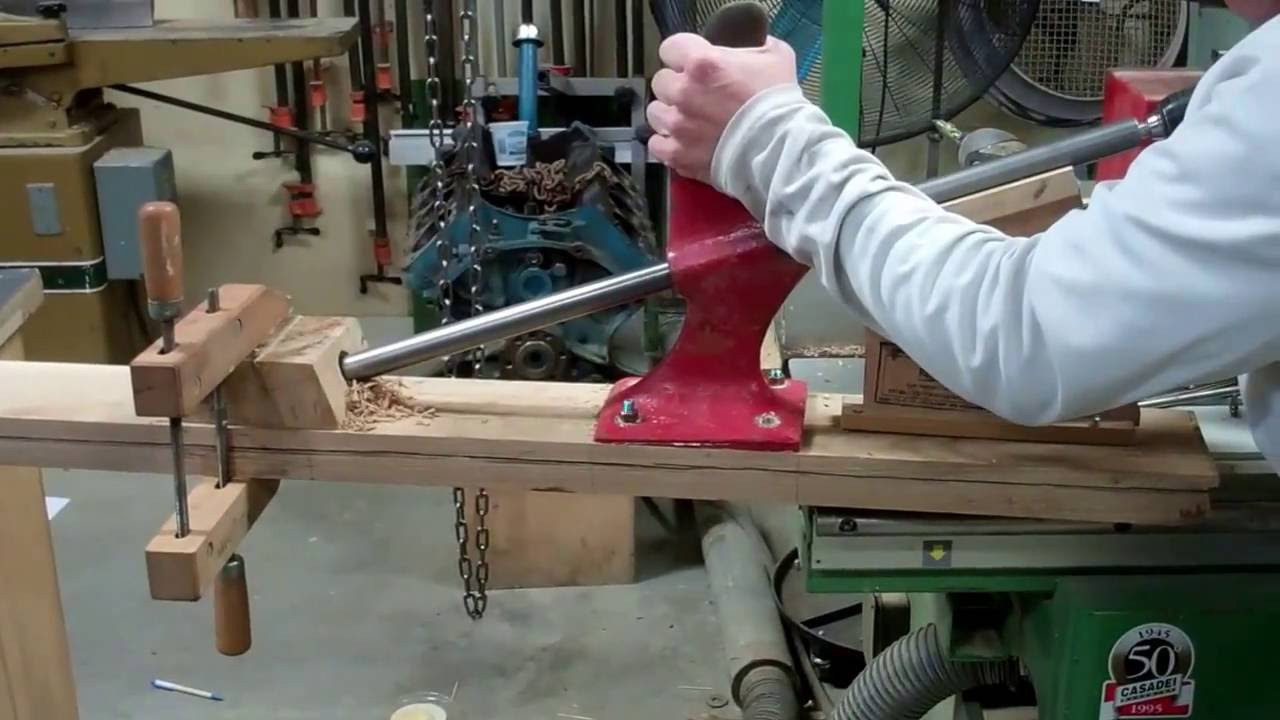

How to Bore a New Prop Shaft Hole – 1946 Gar Wood Ensign

The original keel in this 1946 16′ Gar Wood Ensign had failed completely as we have chronicled in earlier clips on this project. Drilling new rudder shank and propeller shaft holes, and especially the latter, represent a particularly daunting task. If the prop hole is misplaced and/or misaligned, the shaft log will not receive the prop shaft symmetrically, and only bad things follow there from.

Today John and RJ decided that the moment had come, and, with John narrating, this clip introduces you to how we meet these challenges at Snake Mountain Boatworks.

What you will not see in the video is John’s rather ingenious solution to the reality that the Forstner bit tends to cut a tunnel having somewhat ragged and rough walls. John produced silky smooth walls by wrapping the prop shaft, first in progressively finer grits of sandpaper, beginning with 40 and ending with 100

The keel blank is now ready for shaping and fitting to the hull, which we will share with you in the coming days and weeks.