Our attention turns to a task on the 1955 20′ Lyman runabout that, in truth, has been hanging “heavy, heavy over our heads” for some time. The windshield glass on old style Lymans of which this one is an example was originally secured with extruded aluminum stops that are no longer available.

Since these stops were secured with small oval-headed brads, Lyman never cut dado channels in the rabbets. Indeed, this boat’s glass was secured with glazing points and some sort of window caulk that had been stained a “Lymanesque” brown when I purchased her.

Conversations with Tom Koroknay and members of the New England Lyman Group (NELG) all pointed to only one solution: rout the dado into the rabbet and secure the glass with standard, single-spade, white Lyman molding.

“All” we needed to do was rout the dado. The solution, we hoped, would be provided by a 3-fluke router bit slot cutter by CMT. We placed the bearing on the outer end of the shank, with the cutter inside it. Shim washers positioned the cutter precisely so that the glass fits behind the slot and the spade can be pushed into it.

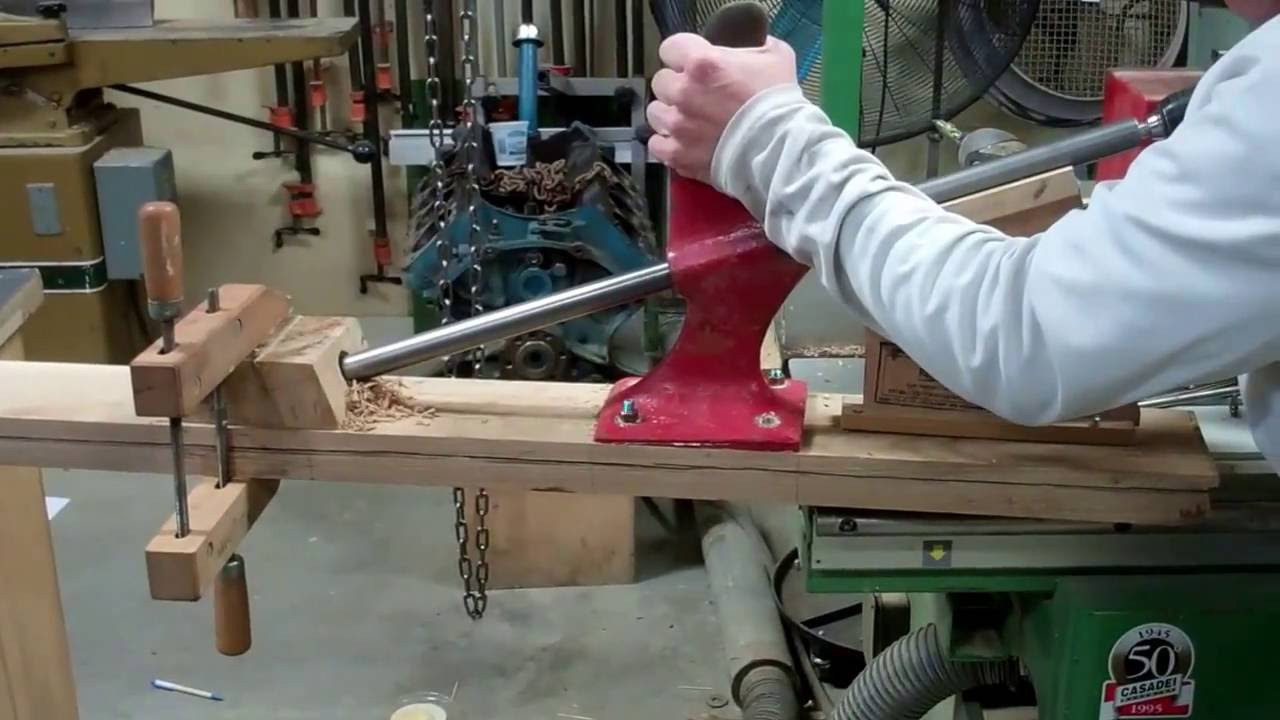

Everything looked good on paper and also on the test piece we made, but that windshield frame, especially the top sections over the front sheets of glass, just looked so fragile. We hedged our bets by building a rough jig to which we could mount the frame using its mounting holes.

In the end, someone had to grab the router and go. John stepped up and masterfully guided the router around all four openings. We have now installed the two front sheets of glass and will install the whole thing on the boat before adding glass to the wings.

Phew! Fabricating an entire windshield would NOT have been fun.