The original keel in this 1946 16′ Gar Wood Ensign had failed completely as we have chronicled in earlier clips on this project. Drilling new rudder shank and propeller shaft holes, and especially the latter, represent a particularly daunting task. If the prop hole is misplaced and/or misaligned, the shaft log will not receive the prop shaft symmetrically, and only bad things follow there from.

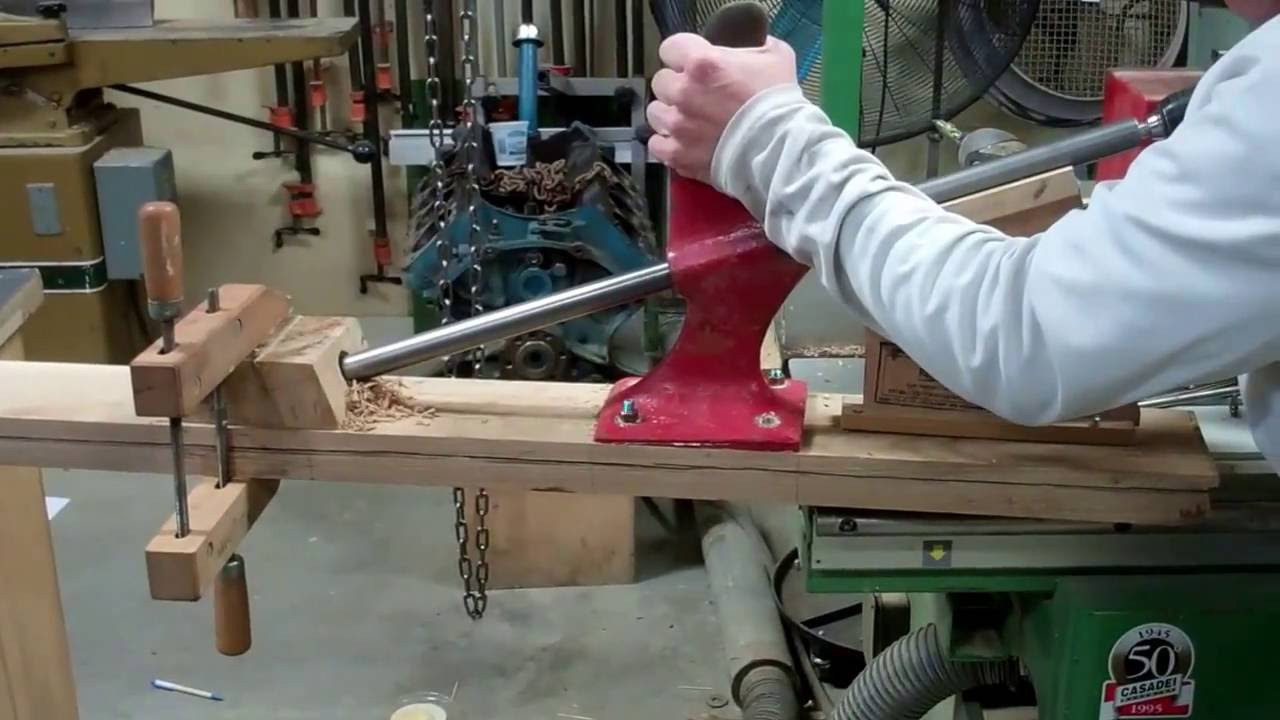

Today John and RJ decided that the moment had come, and, with John narrating, this clip introduces you to how we meet these challenges at Snake Mountain Boatworks.

What you will not see in the video is John’s rather ingenious solution to the reality that the Forstner bit tends to cut a tunnel having somewhat ragged and rough walls. John produced silky smooth walls by wrapping the prop shaft, first in progressively finer grits of sandpaper, beginning with 40 and ending with 100

The keel blank is now ready for shaping and fitting to the hull, which we will share with you in the coming days and weeks.

Vintage Boat Preservation