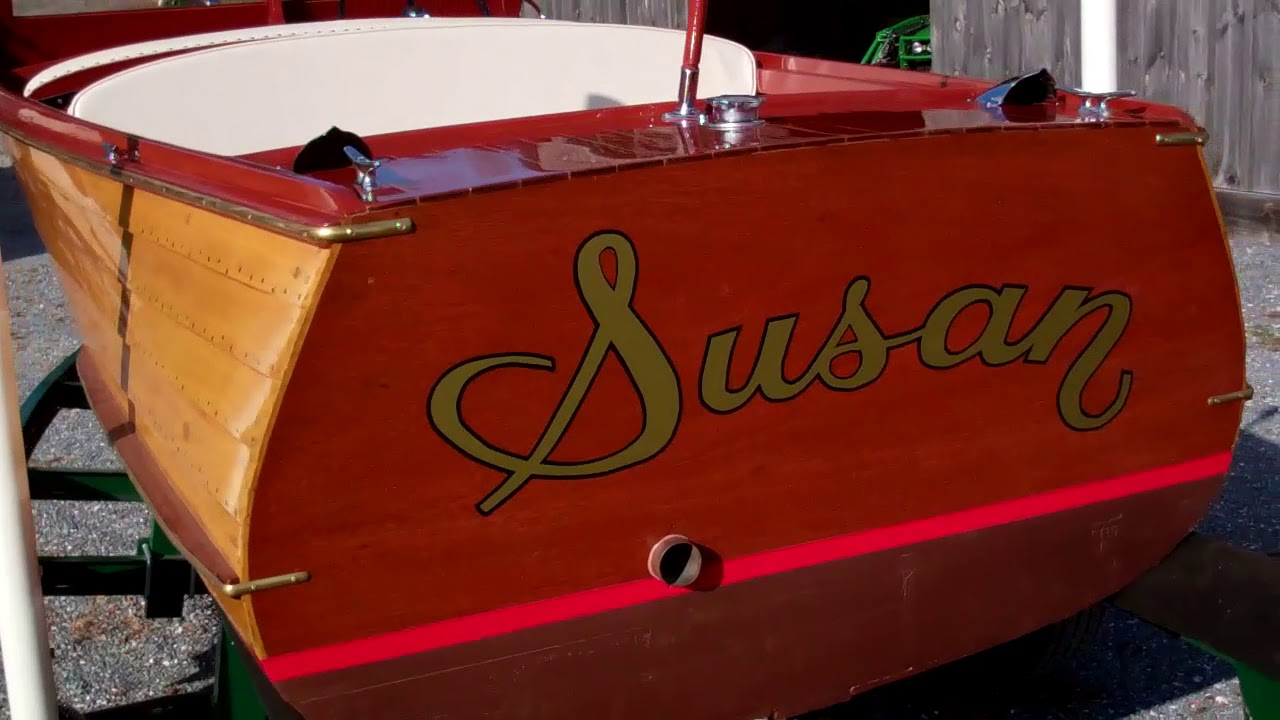

Susan is a Pre-WWII 16’ Lyman yacht tender with solid Cypress narrow strakes and coaming, mahogany transom and decks, aft-facing aft seating compartment, a fixed windshield and a wonderful tumblehome.

She is powered by a Nordberg Gasoline Marine Engine 4-cylinder flathead, 60 horse power, engine, which is mated to a Paragon transmission.

Robert Henkel, Peter Henkel Inc. in Michigan, who executed a comprehensive engine and transmission rebuild, reports that Nordberg “dressed” Hercules engines, in this case a Model B. The Nordberg engine plate includes its own serial number, 130R – 4951.

The person from whom I purchased Susan has owned her twice, the first time for decades ending in 1989, and a second time in spring 2015. She was banished to barn queen status for 25 years by the in- between owners. I bought her from her original owner in June 2015.

Thankfully, my biggest fear, that years in a barn would grow a nice crop of dry rot proved to be completely unfounded. My plastic hammer returned solid, crisp reports everywhere on the boat.

How about the ribs? There simply is no wear, rot or fractures to be found. Indeed, the in-between owner left her outdoors during our recent deluge. The hull is so tight that it held water that had to be vacuumed out.

She has a five-digit hull number, 10151, which renowned Lyman expert, Tom Koroknay, (Lyman Boats – Legends of the Lake), suggests that she may be one of the few 16’, narrow-strake, yacht tenders Lyman introduced in 1931. He places Susan as built in 1940, just before WWII.

Mickey Dupuis and his crew at D&S Custom Metal Restoration in Holyoke, MA, once again transformed tired, pitted hardware into beyond-show-ready jewelry.

Shauna Whiting, Kocian Instruments in Stacy, MN, after much research, preserved Susan’s original gauge panel cosmetically and mechanically with spectacular, historically-correct results.

Megan Meisler, her dad, brother and crew at Loadmaster Ltd. In Port Clinton, OH, once again worked with me remotely and delivered another perfectly-fitting, super-elegant Vermont green trailer.

If only winter was not nigh! We’d have her out on Lake Champlain today!