Paint! I could claim that it seems like only yesterday when we launched the preservation of the mahogany (Brightside) 1946 Chris-Craft U22, but I can’t. In truth it’s been a long, long, and sometimes frustrating slog.

As we replaced most of the bottom and transom framing, both chine frames, and most of both chines; and worked to remove the corkscrew and hog from the hull, days, weeks and months flew by. Were we making progress? Yes, but it was so difficult to see and feel any.

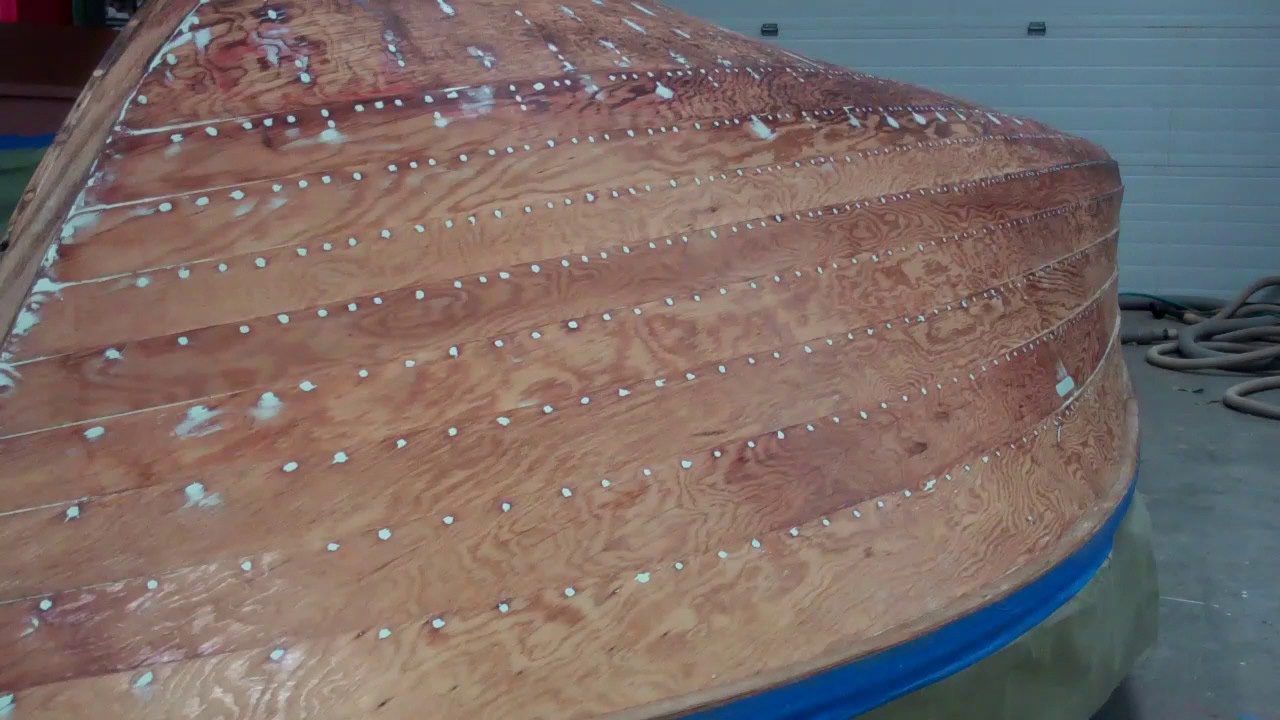

Not now! Her True 5200 bottom is complete to the point of applying her Interlux 2000E InterProtect Primer and her Econominder, copper-free, Chris-Craft blue antifouling paint.

The last of four coats of Clear Penetrating Epoxy Sealer has been applied. Tomorrow, after it has cured, we will hand sand the bottom lightly, thereby preparing a smooth and uniform surface for the first coat of 2000E, which I will apply later today.

We apply the first coat from the keel to the top of the boot stripe, let it cure 24 hours and then mask the boot stripe so we do not build layers beneath the Interlux Brightside Enamel we will use for the boot stripe. Brightside adheres better to Interlux PreKote than it does to 2000E in our experience. PreKote in turn adheres tenaciously to the 2000E.

Four additional thin coats of 2000E will be applied, followed by four coats of Econominder antifouling paint.

Then comes a truly BIG day. We will flip her upright and begin stripping varnish off and bleeding old stain out of the decks and covering boards.

Next comes sanding fair, bleaching, staining and, yes, varnish! Now that will be the day to smile.