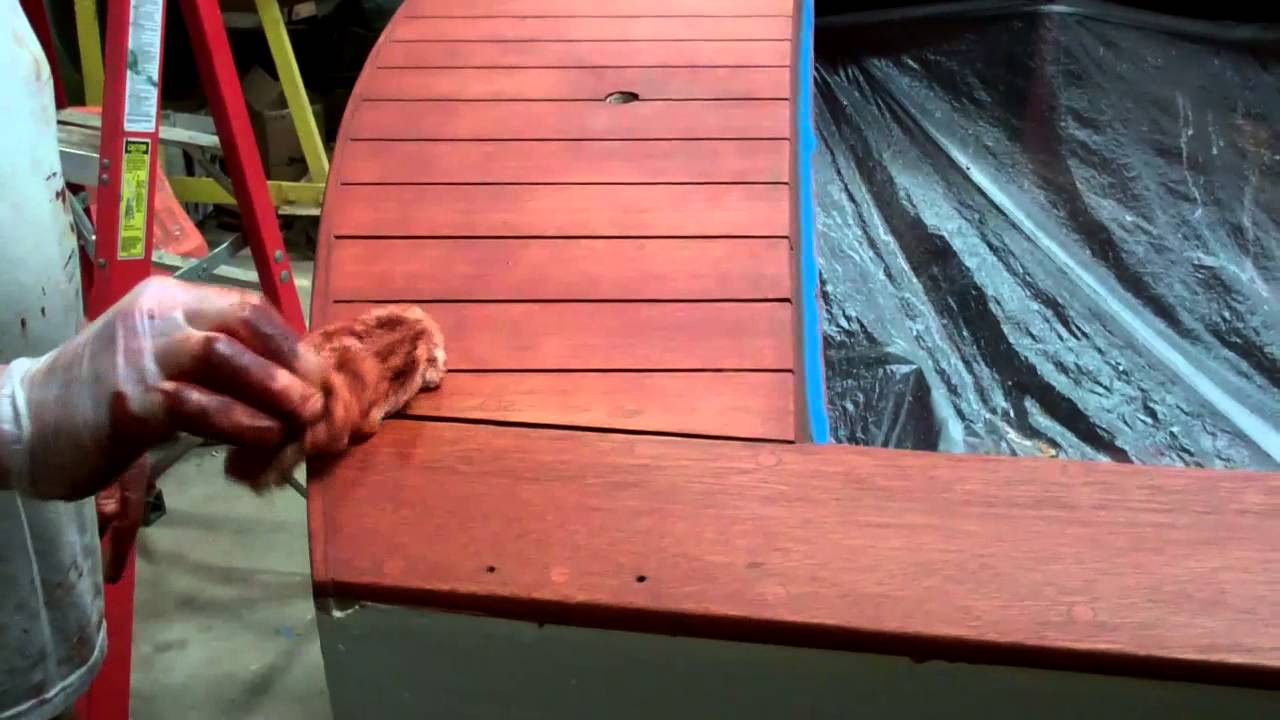

Finally! The 1946 Chris-Craft Brightside U22 is all but completely stained.

Our SMB staining methodology has delivered an absolutely uniform result. What a sight for sore eyes, and especially sore shoulders! Several staining details remain. The dash was modified at some point. The original horizontal chrome strips that were inset into it at Algonac were replaced by marquetry-like blonde wood stripes. These must remain blonde, so John masked them off and stained them with Sandusky Paint Company’s Chris-Craft Corina Blonde stain, let it dry in, and then taped it off along with the rest of the dash. (Since would not be staining the mahogany portion of the dash today, protecting against flying flicks of stain was a must.

Additionally the U22’s bow terminates in a very pleasing pair of triangular planks and a vertical support plank into which the hull number was stamped at the factory. These will be stained and installed after we have applied CPES to and Sikaflexed the foredeck’s (and aft deck’s) seams. For now she will sit for several days, while her newly applied stain is curing. Then we will seal the entire hull with multiple applications of CPES.

The varnish has been ordered.

Yes!