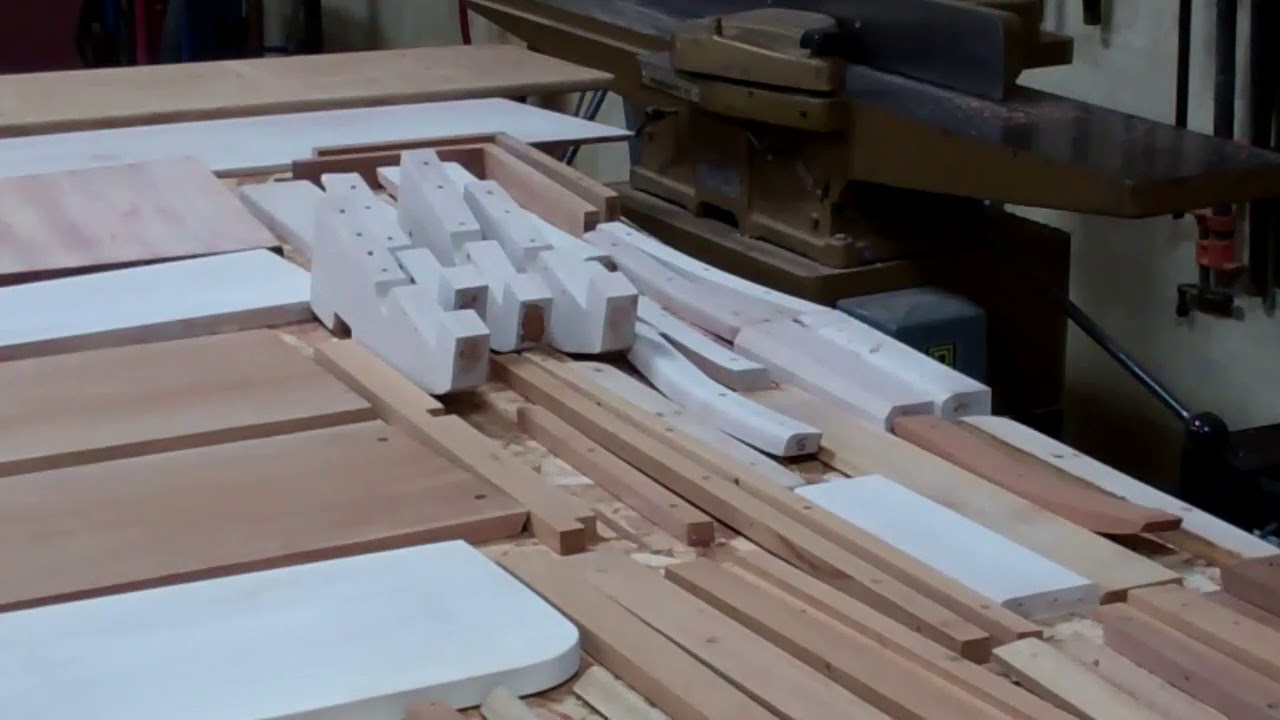

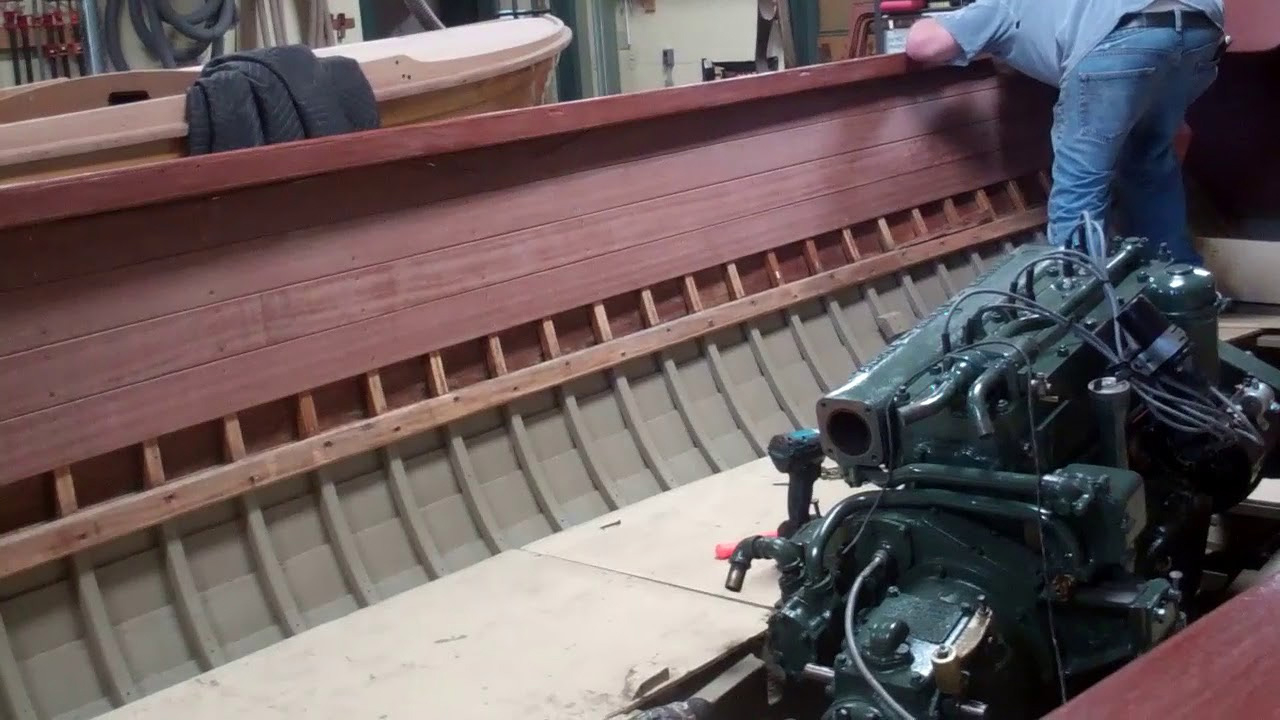

We’ve just blasted through a major milestone in our 1957 23’ Lyman Runabout preservation! ALL parts destined for her cockpit have been stripped, fabricated where needed, test-installed, sanded and bleached.

If you watch one of her recent videos again, you might conclude, as others have, that there were very few parts involved.

And I’ve received multiple emails suggesting we were just exaggerating what was involved in creating and fabricating a pair of jump seats and entirely reconceived helm station seating and lockers.

Well, all I can tell you is that RJ, Joe and I were shocked this morning after we had laid all these parts out in preparation for launching into staining them on Monday. Who would have thought!? Staining is next and, as is detailed in the clip, we will use Wood Kote Jel’d stain for this task. (Available from Super F Paint and elsewhere).

From Wood Kote:

Basic Use

Jel’d Stain is formulated for interior wood surfaces such as casework, doors, trim, paneling and cabinets. It matches the corresponding colors of Jel’d Stain 550 & 250 and Liquid Stain 550 & 250. Jel’d Stain may be applied to bare or bleached wood. It is compatible with a variety of other Wood Kote products. Please refer to the Wood Kote Schedule of Product Compatibility and Recommended Dry Times. Jel’d Stain DOES NOT comply with the US Environmental Protection Agency (EPA) Volatile Organic Compound (VOC) emission requirements for Architectural and Industrial Maintenance coatings (effective 13Sep99).

Advantages

- Matches Jel’d Stain 550 & 250 and Liquid Stain 550 & 250

- Easy to apply

- Fast-drying

- 2-3 times more coverage than liquid stains

- No stirring required

Coverage

One application of Jel’d Stain will cover approximately 1250-1500 sq. ft./gal (30,6-36,8 m2/L).

Composition & Properties

Jel’d Stain is a fast-drying semitransparent pigment wood stain. It is intended for application without thinning. If thinning is desired, PolySolvent (mineral spirits) should be used or, if regulations require a VOC-exempt thinner, use AceThin (acetone).

Depending upon the boat you own or are preserving, contacting Mike Mayer, Lake Oswego Boat Company ([email protected]) will likely satisfy all of your staining needs. Working with Wood Kote, Mike offers roster of Jel’d stains that match original stains for Pre- and Post-WWII Chris-Crafts, Gar Wood, and many more.

If you are after superior quality and consistent stain, and preserving your vessel as correctly as is possible, Mike is your go-to source. Yes, you can mix stain colors yourself and maybe even save a dollar or ten, but you will also suffer the consequences.