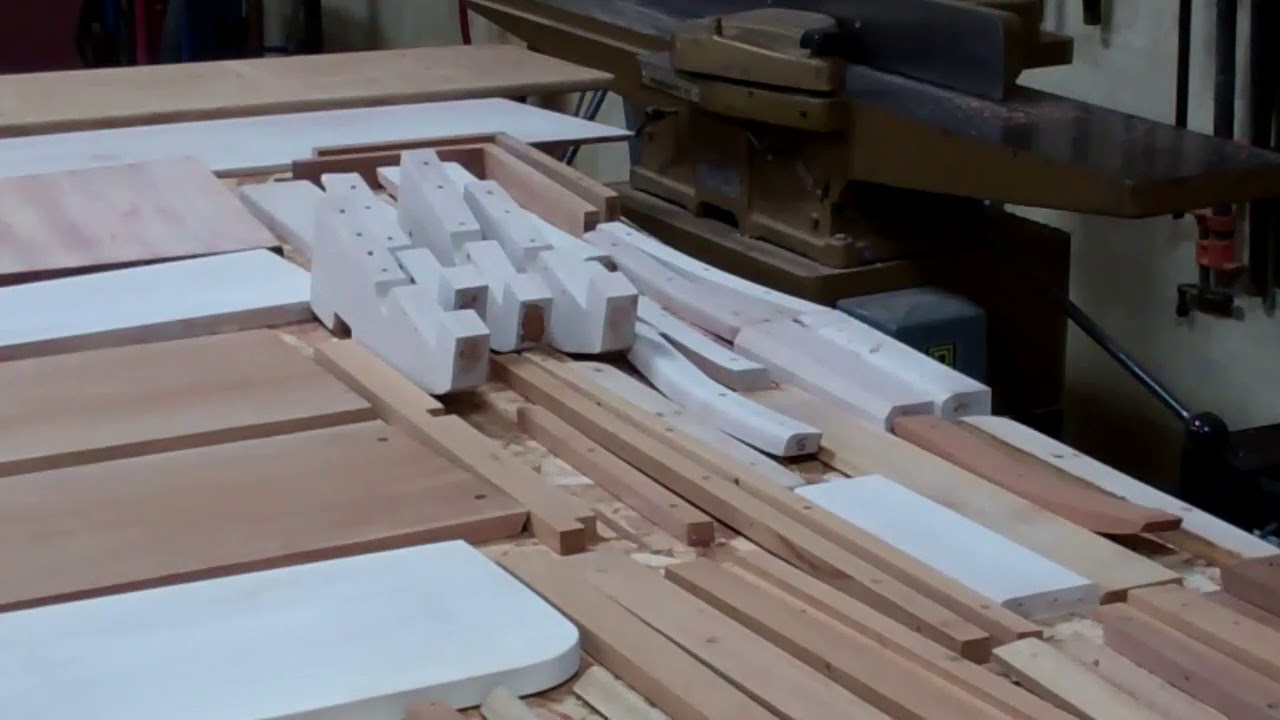

We have released the 1957 23’ Lyman Runabout’s aft seating, both of the jump seats that John designed and fabricated, and all but the three floor panels beneath the helm station.

Joe D’Avignon, our latest crew member addition, who is also RJ’s brother-in-law, brings years of custom designing cabinets and architectural components, trim and moldings for a firm that executed all tasks using hand tools. Nary a C & C Machine was ever in the shop.

Asked why he wanted to work and grow preserving antique and classic wooden boats, Joe replied, “Unlike windows, doors moldings and the like, where it’s mostly a production process once I designed the piece, with these wooden boats, no two challenges are alike. There are no plans to be reached for, and damn few straight lines. Working at Snake Mountain Boatworks involves everything I love doing in wood without the drudgery of repetition day after day. I can grow here in ways that are just not possible in precision woodworking situations.”

Joe disassembled and sanded all surfaces with 80 grit in a straight line Festool Detail Linear Sander. Each piece in each of the jump seats is unique. Nothing is interchangeable, so Joe’s first question was, “How can do you keep everything straight through the sanding, bleaching, staining and varnishing process?”

A combination of painter’s tape and Sharpies?

Joe, “There must be a better, more permanent but invisible way to do this.

Demonstrating how quickly Joe is becoming an asset for Snake Mountain Boatworks, he found a set of HimaPro wood/metal number and letter stamps on a shelf. Armed with these he proceeded to stamp each piece into the end grain after he sanded it. Voila! Amazon offers this boxed set of stamps. We, as well as folks working on this Lyman in the future will appreciate and benefit from this innovation.

Bleaching with Dalys Wood Finishes A&B Bleach begins this morning. Yes, Dalys is available from Amazon, but we source ours from the company, where you will also find a wealth of useful information.

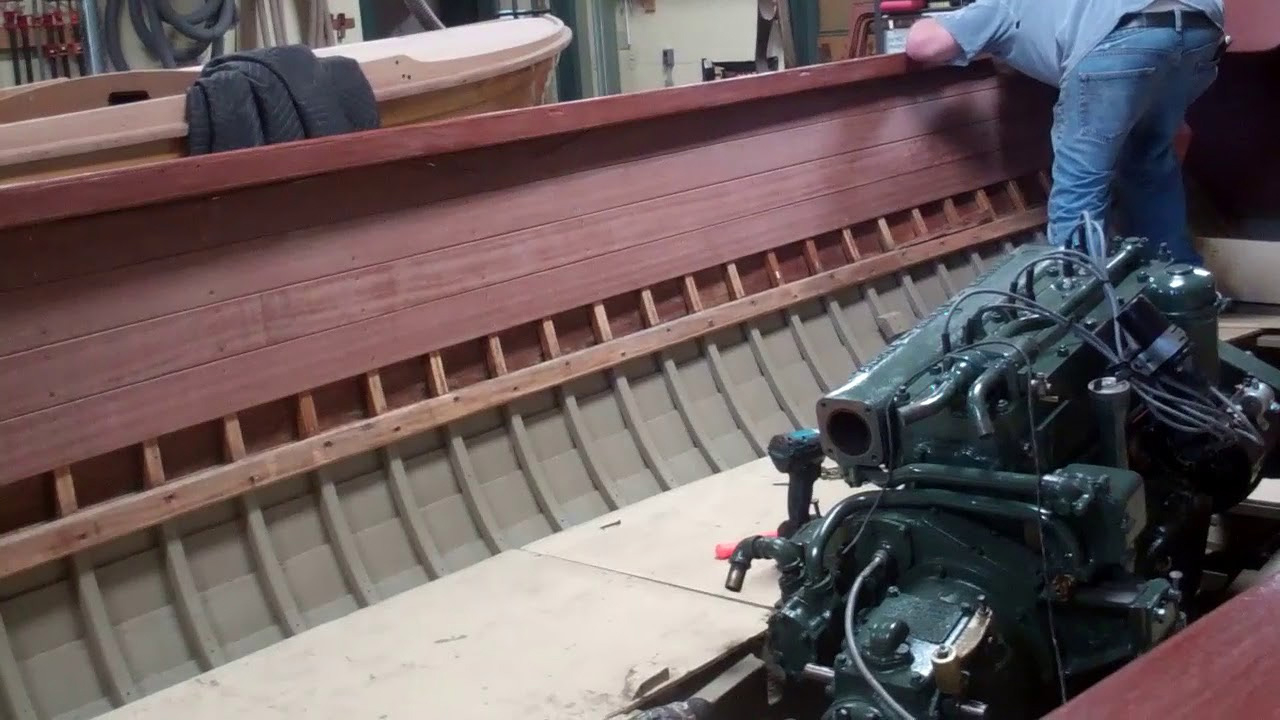

Among the company’s most critically useful recommendations is, always start from the bottom up, lest you create a sea of white stalactites running down your hullsides and transom that are virtually impossible to erase.

RJ engaged some final helm station component fitting this morning. Next comes releasing the entirety of the new helm station seating and lockers, and then all of the ceilings for final sanding, bleaching, staining, sealing with CPES and varnishing. Welcome aboard Joe!