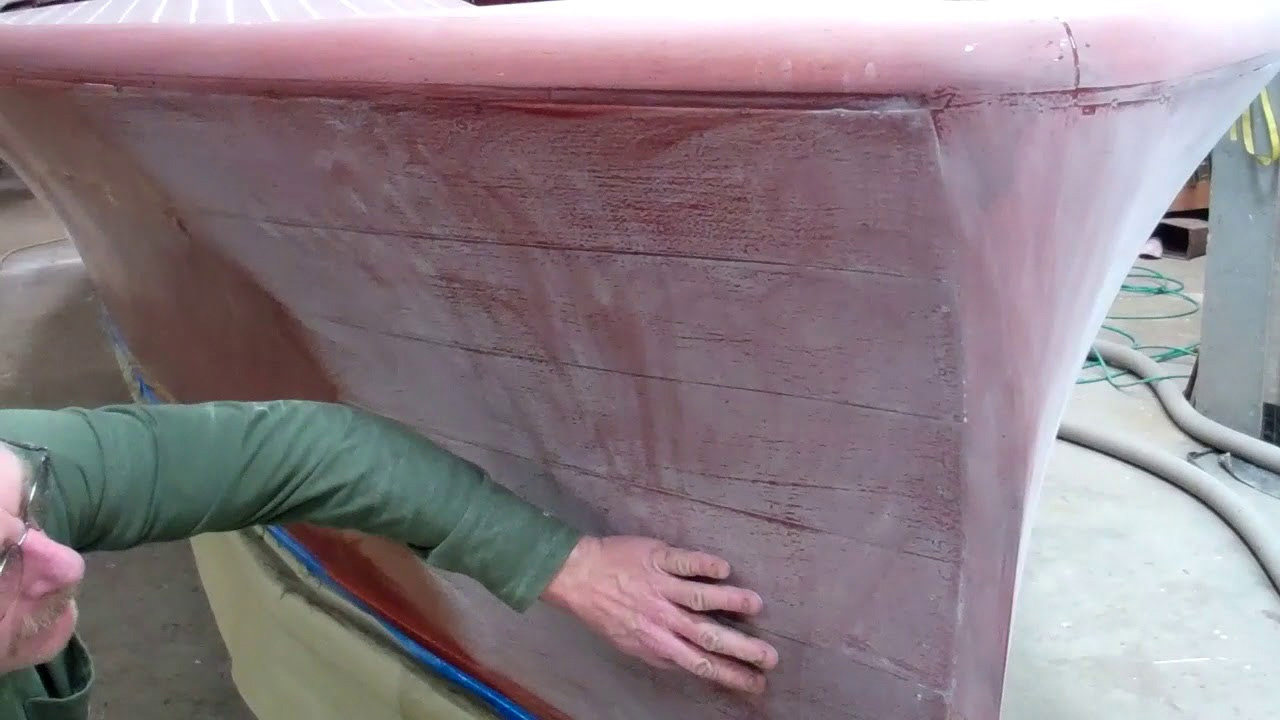

Our 1957 23’ Lyman Runabout’s hull continues to impress us with her originality and condition. Since our last update, RJ and I have focused to prepping the below-waterline strakes, garboards and keel for painting.

We have previously noted the Dutchman repair work awaiting John on the stem, knee and gripe. We have now added Dutchman repair needed on the keel about amidships. And we did find many loose strake fasteners that we tightened or replaced, but we have yet to discover any rot. Our fastener work followed stripping gobs of paint from and tightening the bottom strakes and garboards.

Fairing is next, a project we have nearly completed on port with the application of the third coats of 3M Marine Premium Filler. Starboard will be next.

Then comes sanding everything fair.

John took me to task for suggesting that we will sand with our random orbit, reminding me that, for runs as long as this hull presents, we will sand with our 18” Hutchins longboard sanders. Using the random orbit risks sanding undulations into the surface. (We will use the random orbit for short runs like the below-waterline area of the transom.)

It won’t be long before we are priming the bottom with Pettit Tie Coat Primer 6627 and then applying multiple layers of Sandusky Lyman Copper Bronze Antifouling paint.