We are at the most enjoyable point in each of our restoration projects. Every bit of stripping and deconstuction is behind us. The lapstrake topsides and boot stripe have received their final coat of Totalboat Wet Edge polyurethane paint.

We could not be more pleased with the new-to-the-markiet paint line from Jamestown Distributiors’. Wet Edge is positioned to challenge Interlux Brightside. We have tested it on half a dozen topsides by now, and will standardize on this paint, one which trumps Brightside by every criterion, but especially in terms of gloss and a curing process that leads to a virtual complete absence of brush marks. (We roll and tip this paint, and have applied three coats over three of the primer.)

The bottom was scraped completely clean, before 3M 5200 was applied to seal every seam. She then received three coats of Pettit Tie Coat Primer, followed by three of Sandusky Lyman Tan Antifouling paint.

We have four coats of Captain’s Varnish Ultra Clear 2067 on the transom and two on the decks and covering boards as I type. The ceilings are next.

Using Captain’s grows out of conversations with several well-respected Lyman owners whose judgement I respect. Since she is a SMB-owned boat, she’s become our test vessel for purposes of bright work.

If you search back through the clips we’ve posted to this challenge, you will see the same boat being stripped of what ended up being 95 pounds of paint from the topsides alone. She was just as “crusty” below the waterline, but collecting and weighing those “leavings” proved impossible.

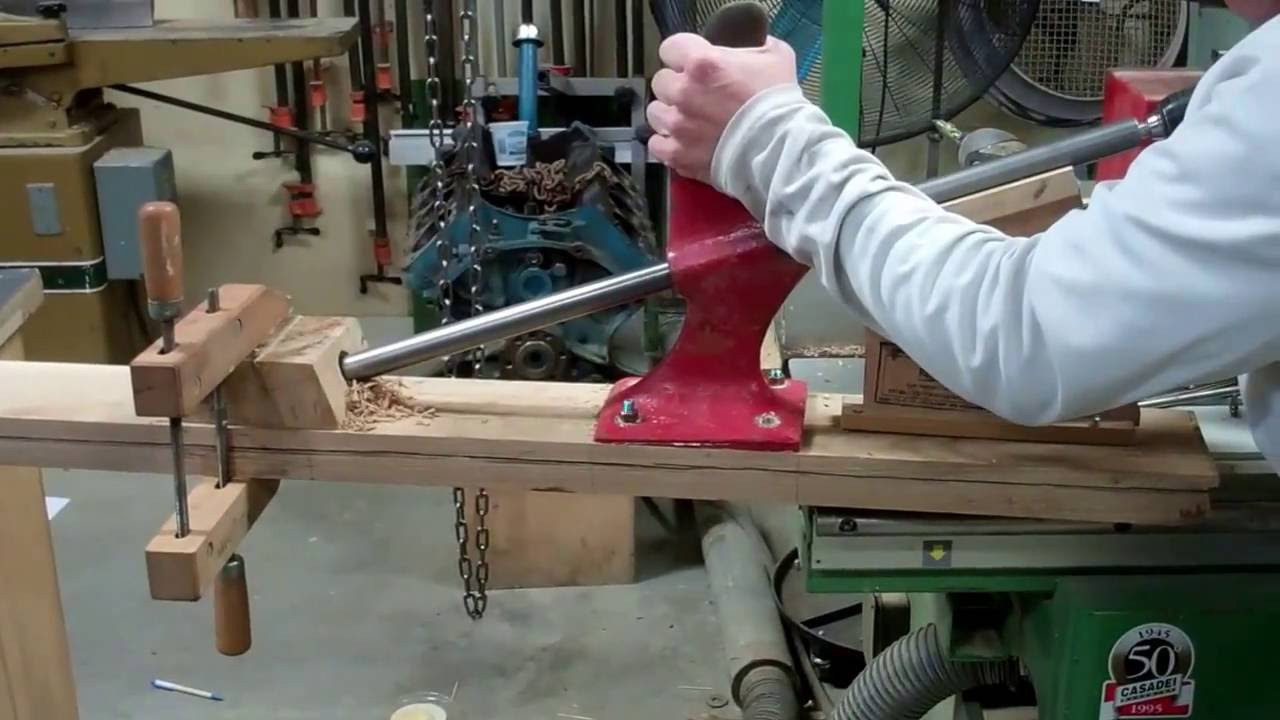

Stay tuned for more updates. Once we have the ceilings installed, her completely rebuilt Chrysler Crown engine will be installed, followed by her floor panels, which have been updated with new Nautolex in natural.

We are racing against the onslaught of winter, and it looks like winter will win. The sea trials we hoped to run this fall will likely wait until the ice leaves Lake Champlain next spring.