Captivator is a 1954 Penn Yan Striptite Captivator Aristocrat who is fitted out with virtually every option Penn Yan offered on this model in 1954.

We faced some major issues upon her initial inspection. Her transom and transom framing were rotted beyond saving, so were replaced.

Someone had tried to caulk her inter-plank seams with a 3M5200-like material, most of which had long since lost its adhesion. Removing all this material using reefing hooks cost many hours, but in the end, her seams were clean.

After removing her keel and keelson, which provided access to area internal to the keel, and inspecting the entire hull below the waterline, the only rot discovered lurked behind her improperly-installed spray rails.

Whatever was used to “seal” the spray-rail-hullside seams had long since failed, which allowed water to work down behind the rails and stay there. Rot was evident, and Joe’s foray into Dutchman repairs followed.

Save for saving the upright braces, Joe and RJ fabricated all new transom framing and then a two-plank transom blank, all of which matched the pattern pieces exactly. Many hours of fitting and sanding later, Captivator’s new transom was in place and the original brass protective strip had been reinstalled.

Once it was properly caulked-sealed using TotalBoat Thixo Flex, we flooded her hull below the waterline with three full coats of Clear Penetrating Epoxy Sealer (CPES) and allowed it to cure for 48 hours before applying three coats of Pettit Tie Coat Primer 6627. We finished the bottom by applying four coats of JD Select Ablative Bottom Paint in shark white.

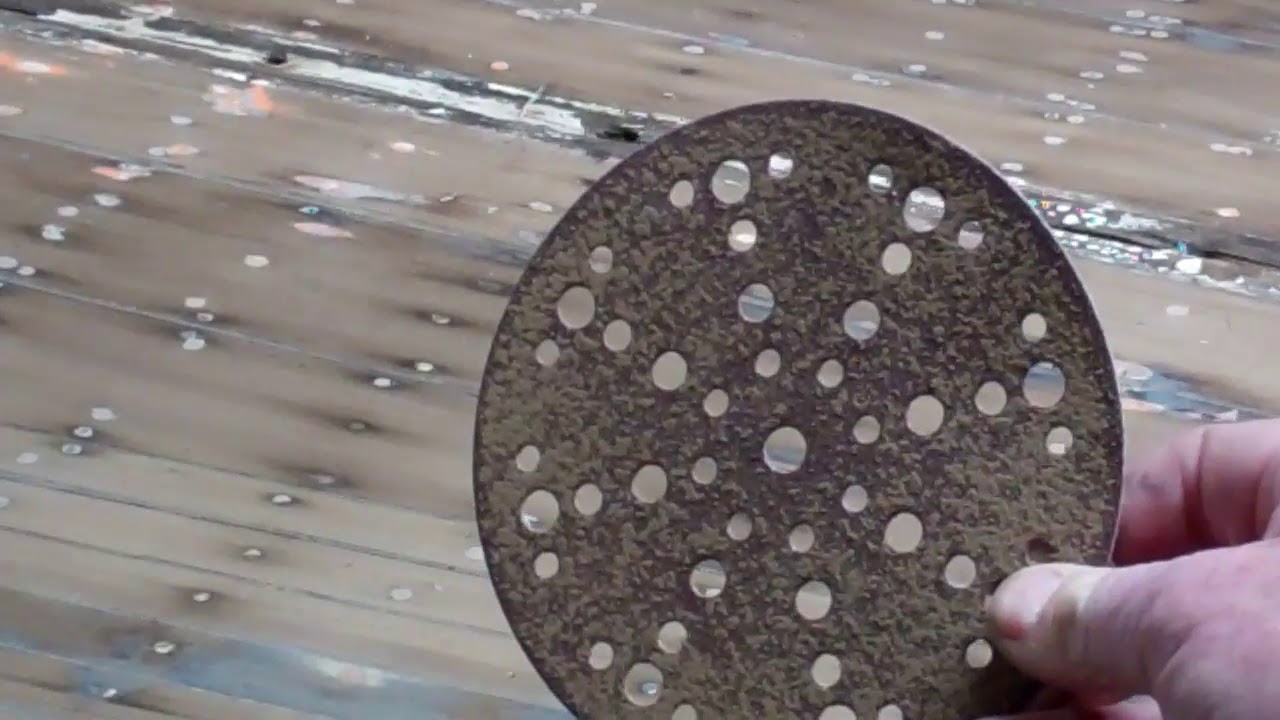

We stripped her hullsides, decks and gunwales to bare wood using our trusty Circa 1850 Heavy Bodied Paint and Varnish Remover.

All that wood was sanded fair, stained using Mike Mayer’s, Lake Oswego Boat Co, post-war CC gel stain. (Mike can be reached at [email protected], or www.loaboat.com).

Her deck seams were payed with mahogany Sikaflex 290 LOT mahogany The standard sequence followed: CPES, scuffing and then varnishing. Her decks, hullsides and transom received 18 coats of Pettit Hi-Build followed by 3 coats of Pettit Captain’s Ultra Clear 2607. Hand (block) sanding with increasingly fine grit until the final sanding was executed every 5 coats or so until she received her final coat.

Interior surfaces received 18 coats of Hi-Build.

Reassembly followed, and now she’s ready to go home.